| Author | Message | ||

| rick00000

Rating: N/A |

Does anyone have a fix for a plastic shower pan that has numerous cracks on the bottom. I do not want to replace the pan yet. I was thinking about a elastomeric coating that was flexible yet easy to clean as it will see shower water. | ||

| niles steckbauer (Niles500)

Rating: N/A |

Rick - I'd cut chopped fiberglass mat to fit w/in bottom of pan - scruff the floor up - glass it - white epoxy paint - and your done - chopped mat acts like a non-skid surface - HTH - Niles | ||

| truthhunter@shaw.ca Rating: N/A |

I poured in high strength concret in the one in my basement, but in your bus you are not likely to have the extra 2" to spare and then the extra 80lbs of weight to, but it was a cheap fix that is still holding out well. | ||

| WEC4104 Rating: N/A |

Rick: I am following this thread, and the one on the other board, because I'm facing something similar to you. I have a half tub with a built in step that has developed some small cracks, and I've been wondering about what material I might use to fill them in. Someday I will want to replace the whole unit (and it's wonderful 1970's dark mustard color) but for now I haven't found a replacement of the right size and drain configuration. The other thing I am wondering has to do with the support underneath. I am asking myself why it cracked in the first place. If it is not properly supported, it doesn't matter what I fix it with, it will probably be no stronger than original, and therefore crack again. Has me considering adding extra bracing underneath, or possibly extra layers of fiberglass to underside. Niles' comments about the white epoxy paint has me thinking too. | ||

| John MC9 Rating: N/A |

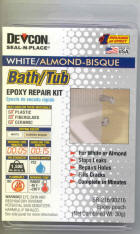

Any RV shop (and Walmart), carries a product designed for this. It's for the sole purpose of repairing the type of plastic shower stalls are made of. The kit is around $7.00, and comes in White or Almond. Tub Repair  | ||

| John MC9 Rating: N/A |

"The other thing I am wondering has to do with the support underneath." I reinforced the shower base in a Winnebago, by using high density expanding foam... the spray can type. Don't try to use the high expansion type, since it'll push the base upward. The low expansion type will fill the voids and give remarkable support to the base of the shower! (Find it at Lowes, Home Depot, Ace Hardware or Walmart). | ||

| Crane Rating: N/A |

-----Any RV shop (and Walmart), carries a product designed for this. It's for the sole purpose of repairing the type of plastic shower stalls are made of. The kit is around $7.00, and comes in White or Almond. ----- John, did you use this fix??? does it cover the whole pan? Will it color over a fiberglas fix in the pan? Thanks for your thoughts | ||

| John MC9 Rating: N/A |

That kit will fix a decent size crack or rip, but there's not enough to do the entire pan, edge to edge. I have used it over fiberglass, and it adhered well. The Almond color covers other colors well. If you're going to do the entire pan over due to excessive cracking, you'll be taking a chance ... Water can ruin your new project.. Cracking plastic can't be trusted, and there's no magic with these temporary fixes... You can't bring old plastic back to life. But... If you insist...With the packets of this stuff, you'll need quite a few.. maybe $30 - $40 worth.. Try one packet, and see for yourself. Give it time to dry before attempting to layer on a second coat. It's an epoxy, so you may be able to use some other brand that's less expensive. Epoxy is epoxy.. You can use an epoxy paint to make it all the same color. It saved one RV bathtub from being replaced.... didn't leak for the cpl years I owned it.. And as far as I know, the guy that bought it is still using it. No leaks that he's told me about.. | ||

| rick00000

Rating: N/A |

I have numerous cracks about 4-6" long that are due to poor support under one section of the shower base. I would like to cover the whole base bottom with some product that can flex and still be waterproof. I am going to change the pan later , not now, no time before our trip to Ak. Some body came up with the idea of truck bedliner spray-in stuff, anothe r was buy vinyl flooring and glue to base and caulk the edges. another was ceramic tile with flexable grout...I don't know about the flex grout? | ||

| John MC9 Rating: N/A |

The guy that owned our Winnebago (sold it to me), tiled the tub pan. It fell apart after a few showers, and leaked like hell.. Without good support, plastic will give and flex, and any solid material like tile, and the grout around it, will crack and fall apart. It ain't rocket surgery. I forgot all about that Winnie.... I used the low expansion foam under the pan, and that same epoxy kit for those cracks. And painted it with Krylon epoxy paint, to match the walls. Worked great.. The Winnie pan (from Winnebago) was around $250 at the time... "Special order/design"... Phoooie. | ||

| Crane Rating: N/A |

My bus has a very oddly shaped shower space, that said, nobody but NOBODY makes what I need. The plan is to make a form of this shape, including inclines, sides and drain hole, fiberglas it, then color it. This can be done for well under $250 and you can make your own unique shape. If you like the look of wood, you can use a good looking wood, when you fiberglas it, the glas will be invisible and the grain of the wood will come through. You need to make a good lip at the drain hole for the drain parts, or a sump if using a pump. Maybe, time wise, it would all tally up to $250 or more, since the manufacturers make them in quantity and they have the cost advantage. But I look at it as I AM NOT PAYING $250 buckeroos. Fiberglas is not that hard to shape, quite easy actually, you just need space to do it and time. Jus My Thoughts Crane | ||

| Stephen Fessenden (Sffess)

Rating: N/A |

I had a similar problem, not a leak but a worthless ower pan. Use only epoxy with the fiberglass matt. You can really stiffen it up with carbon fiber matting or cloth. That was my problem: too much flex on the shower pan after 20 years. A good source of materials is RAKA, www.raka.com . They will ship what you need and give excellent advice. BE SURE YOU DESIGN A PLUG FOR THE DRAIN. Resin will seep every where it can. I unscrewed the drain and replaced it with a 4 inch pvc pipe with cap until I was done. This is also a good time to improve the drainage of the shower. Put the bus out of level so that the corner opposite the drain is lowest. Good luck. |