| Author | Message | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 197 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

I have a 1965 Kohler 7.5KW gasoline genset - formerly Marine, converted to radiator. The radiator is remotley mounted in the former air conditioning bay, and the genset is in the first baggage bay. I just built an enclosure for it and I'm trying to determine wheter or not I need better ventilation. According to the people I have bought parts from, the thermostat should keep the engine at 170. So, I'm trying to determine exactly WHERE it should be 170 with my IR gun. The outside temp is about 65 degrees. Here are my readings - Radiator tanks - between 130 and 170 Radiator Lines - between 130 and 170 Engine Block - between 190 and 215 (very close to the water cooled exhaust manifold for the higher reading) My electric gauge is reading just over 190. It mounts in a brass extension tied into the cylinder head. (Could that be giving me a false reading?) I just put a new radiator cap on. The old one was puking at 180. The engine is running smooth, without any visible exhaust gas. I was getting these readings while running a fridge, 2 roof airs, my Xantrex 4024 in charge mode and it was bulk charging my house batteries. That's as much of a load as I can imagine running. Maybe I'm being paranoid, but I'm about to do my first dry camping and I've never relied on my genset and inverter. Thanks in advance! Glenn | ||

| Jack Conrad (Jackconrad)

Registered Member Username: Jackconrad Post Number: 1022 Registered: 12-2000 Posted From: 71.3.157.139  Rating: N/A |

Glen, Temperature senders are usually installed in the engine just below the thermostat and installed so that the thermocouple part of the sender is in the flowing coolant. I would shoot the temperature of the thermostat housing (engine side of the thermostat). When does the coolant flow through the exhaust manifold? on its way TO the radiator or FROM the radiator. the coolant should flow through the exhaust manifold on its way the radiator (after leaving the engine), so it does not re-heat the water entering the engine.l Jack | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 198 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Jack, The cooland does flow from the exhaust manifold to the radiator. That hose shows abut 170. The return line shows about 130. I'll shoot the head at the base of the thermostat housing this morning. Unfortunatly, there doesn't seem to be a spot in the head any closer than it's current location for the thermocouple other than the side of the head. However, it is in a T that I had attempted to run a heater core from. I left it on when I removed the core. I'll get the thermocouple right into the head too and report back. Thanks! Glenn | ||

| Bill Gerrie (Bill_gerrie)

Registered Member Username: Bill_gerrie Post Number: 248 Registered: 3-2006 Posted From: 216.198.139.38 Rating: N/A |

Glenn Gen sets run fairly hot with a load on it like you have. On mine I had to put an extra electric fan on the rad for when the temperature outside got hot. It runs about 180 with both fans on when the outside temp is 90 or more. The high reading near the exhaust manifold would be normal especially under load. If your gun shows 190 around the area where your gauge is I would assume things are normal. It is best to put the sender back into the head instead of in a "T". It is in better contact with the coolant. Most gen sets have an automatic shut down on over temp or low oil. Bill | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 199 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

So here's the update. I moved the thermocouple in and checked the temp on the head immediatley below the thermostat housing. It reads 190. My electric temp gauge reads the same or a little less, and the mechanical gauge installed in the side of the head toward the rear of the engine is also reading 190. The outside temp is 50 degrees. I'm running the same load on the genset. So, it seems the enclosure isn't too much of a problem, but perhaps I need better cooling to keep it at 170? I'm running an automotive fan pushing air into the radiator and have a squirrel cage fan in an enclosure behind evacuating out the hot air. Any chance on a hotter day, the genset would just run hotter? Both last night and today, it sounds great. No heavy exhaust, no misses. Maybe I am being paranoid? Glenn | ||

| Don Evans (Doninwa)

Registered Member Username: Doninwa Post Number: 196 Registered: 1-2007 Posted From: 208.81.157.90  Rating: N/A |

Glen, I would see where it runs with a minimum load. Maybe one air after heating it up with a full load. If it stays at 190, it might be what the thermostat wants. Do you know what the thermostat is actually rated for? How far is the radiator from the engine? You may not have enough circulation. In a marine application there is a unlimited supply of cool water. Good luck Don 4107 | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 200 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Don, The thermostat I bought from the only place in the midwest that services this old of an engine, and it even requires a special housing to make it work. No doubt about it's rating. I'll give it another run with a light load to see where it stays. The radiator is less than 2 feet from the engine. Thanks! Glenn | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 201 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

OK - After further testing, it runs right about 170-175 under a light load according to the gauges. Light load being the inverter charging house batteries. Looks like it's going up to about 180 with an air conditioner on. Thoughts? Thanks! Glenn | ||

| David Evans (Dmd)

Registered Member Username: Dmd Post Number: 309 Registered: 10-2004 Posted From: 173.77.212.104  Rating: N/A |

Sounds like its doing its job,as the load increases so does the heat. As long as your cooling system can shed all the heat you should be fine. Make sure you have plenty of air over the unit also but it doesent sound likes its too hot to me. | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 202 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Thanks David! It's running very nicely! I'd just hate to see it creep higher if the ouside temp was around 90. Glenn | ||

| Chuck Newman (Chuck_newman)

Registered Member Username: Chuck_newman Post Number: 324 Registered: 1-2005 Posted From: 99.0.41.3  Rating: N/A |

Glenn, I'm interested in the outcome of this as my eventual gen/radiator placement will be the same as yours. Except I am planning on using only one high flow suction fan. Running two airs, frig (I assume it AC compressor type) and 4024 (depending on batt charge) you are loading the gen around 4KW or more. That's about 60% load on the gen. All the coml gens I installed recommended no greater than about 60%. So at that load, I would expect a temp of 170 to 175 degrees with a 65 degree ambient. Two things I've run up against in the past: 1. Per several engineers, a fan pulling air through a radiator is more efficient than a fan pushing air through a radiator. 2. In either case, I've found you must limit the air flow around the radiator as much as possible. This is air the radiator is not benefiting from. That's why vehicles have radiator shrouds and air dams installed. Also, IF your fans are operating in series configuration in an otherwise sealed chamber, I have read where different flow rates and efficiencies between fans can cause either a back pressure problem or a partial vacuum problem. In either case, air flow is reduced and cooling efficiency drops. | ||

| Chuck Newman (Chuck_newman)

Registered Member Username: Chuck_newman Post Number: 325 Registered: 1-2005 Posted From: 99.0.41.3  Rating: N/A |

I forgot to add, if the gen has carboned up over the years, that will increase operating temp with increasing load, even if the cooling system is perfect. That being said, I have seen that effect on 100KW gen sets, and Dick Wright says carboning of smaller units generally does not occur. FWIW | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 203 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

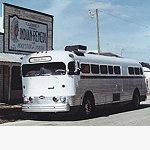

Chuck, Lots of great info there! My fridge is a norcold model, and i think those don't have compressors? If you think with the load of 2 roof airs, fridge, 4024 the temp should be between 170-175, then I'm having a problem since I'm running around 190 under that load. Here's the radiator. I built shrouding that covers the squirrel cage. It sends air out the original vent in the floor. The gaps between the radiator and the shround are all duct taped up. It is possible that the pusher fan is a greater cfm than the squirrel cage. <img> | ||

| Tim Brandt (Timb)

Registered Member Username: Timb Post Number: 298 Registered: 10-2003 Posted From: 74.244.14.221  Rating: N/A |

Glen, A couple things come to mind. From the photo of your radiator you have quite a gap at the top not covered by the shroud so the fan is going to be pulling air from that gap rather than through the radiator. The other since you retained the cooled exhaust of a marine setup there is a lot of extra heat load that imparts. When you consider seawater even in the warmest areas is 80 degrees pushing 170 degree water from the engine through that and then to the rad requires that the rad shed a lot of heat. Just my best guess | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 204 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Thanks Tim! I see the gap you are referring to. I didn't think it would matter since I am pushing air into the radiator, and then it is being pulled by a squirrel cage through the radiator and out the bottom of the bay. Am I wrong? It's really easy to block that off with a piece of aluminum. A thought on the water cooled exhaust - the coolant flows from the thermostat housing through a hose, then to the exhaust manifold, then out again to the radiator hose. Should I bypass the manifold? Thanks! Glenn | ||

| Marc_bourget (Marc_bourget)

Registered Member Username: Marc_bourget Post Number: 5 Registered: 10-2006 Posted From: 64.142.42.176 Rating: N/A |

Lots of good observations in this thread. The issues are many and varied - too much to attempt a response of sufficient detail to actually help. All those wanting more info, consider attending my seminar on cooling systems at Rickreal this year. I'll cover the point from an automotive engineer's perspective on cooling systems and, once again provide some graphic evidence of what can make a DD 2-stroke overheat and ways to deal with it. The points made will apply equally well to Genset installations as they do to propulsion engines. onward and upward | ||

| Chuck Newman (Chuck_newman)

Registered Member Username: Chuck_newman Post Number: 326 Registered: 1-2005 Posted From: 99.0.41.3  Rating: N/A |

Glenn, We went shopping since my post here, and as usual, it gave me time to reflect. I have a 1983 Toyota. Original everything except water and fuel pumps, and alternator. About ten years ago it began to run hotter with same terrain and loading. Mechanics checked it -- everything fine. I did some research and a lot of info that engines naturally run hotter as they age. So I accepted that. About 4 years ago it started to run hotter in cold weather. Into service again several times over several years. A new radiator, new hoses, new water pump, new fan clutch, etc. They did some work. I did some work. All seemed to help somewhat. But it still ran hotter than it should. Then recently I found a couple very small leaks. Had them repaired, and a second water pump installed, and the weather is getting hotter here now. Low and behold, the 26 year old truck is not overheating, and more amazing the running temp is now back down to the level it was when new. Haven't seen that in over 10 years. The moral of this story is everything that everyone has contributed regarding your issue can be relevant for any engine, but the bottom line is if the entire cooling system is not in peak condition, and I'm talking the water portion here, then it's going to run hotter than normal with load. And the engine temp will markedly increase with load. Just an observation of years of frustration. | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 205 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Final update (I think! ;D) I bypassed the water cooled manifold and what do ya know - with 2 roof airs, 4024, and fridge it stays at 170-175! I attempted to run it without the pusher fan, but the temp climbs back up to 190. The pusher fan will bring it back down slowly. I now need to put a temperature controlled switch on the pusher fan to automate that system. Thanks to everyone who helped! Glenn | ||

| john w. roan (Chessie4905)

Registered Member Username: Chessie4905 Post Number: 1411 Registered: 10-2003 Posted From: 71.58.110.9  Rating: N/A |

You might want to add some Redline water wetter or another equivalent to the coolant. It will improve the heat transfer properties. I think it is also made by royal purple. Read the instructions on the container. Don't overdose it. Also made for diesel engines, but a different mix. | ||

| Tim Brandt (Timb)

Registered Member Username: Timb Post Number: 299 Registered: 10-2003 Posted From: 74.244.14.221  Rating: N/A |

THanks Glen. I missed the part about it being a pusher fan. If the squirrel cage on the backside covers the entire radiator that may not be a factor. I wish I could advise you on the exhaust manifold. I have used them many times on boats but never looked into whether you can just remove the cooling without any ill effects. It may be possible that the fan is more CFM than the squirrel it's also possible that if it was designed to be a pull type and you just reversed the polarity of the motor that the fan blades do not work as well in reverse. (Message edited by timb on April 19, 2009) | ||

| Luvrbus (Luvrbus)

Registered Member Username: Luvrbus Post Number: 692 Registered: 8-2006 Posted From: 24.251.187.171 Rating: N/A |

Glenn, I would check the timing on your generator engine I had a Onan that would heat up under a load.Onan advanced the timing and sloved the problem. good luck | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 206 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Well, it looks like I missed a bunch of posts before I made my last one! I'll try to explain how this marine set originally ran, and then how it was modified before I got it. This type of unit has 2 water pumps. One to draw fresh water in from the lake, push it through the water cooled exhaust manifold where it would be split - into the exhaust, and into the engine water pump. The engine water pump would circulate the water through the engine,through the thermostat housing, into the water cooled exhaust manifold where the process would repeat. My lake water pump intake was re-routed to accept the water that would have gone into the exhaust, basically just creating a loop in and out of the water cooled manifold. Useless, and I also suspect that the impeller on that pump has been removed. It's basically just a belt tensioner. By disconnecting the radiator line from the thermostat housing that ran to the water cooled exhaust manifold and attaching it directly to the radiator, the cooling system now operates just like the non marine version of my genset. Chuck - Now I can report: No leaks, new water pump last fall, aluminum radiator, new hoses, new thermostat. Like your Toyota, once everything is replaced, things usually work!  John - I did put that in last season, and the engine ran great, but I didn't have the inverter and the electrical completed, so I never had a chance to really test it. Now, I've done enough work on it I think I've diluted it! I won't forget it though if I need it. Thanks! Luvrbus - I'd hate to think about that! It's just a gear driven cam, and it shouldn't be able to change. And also, like I say, it runs great! I just needed to be sure that I could let it run for several hours without me worrying over it! Thanks! Again, thanks to everyone who's helped! | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1555 Registered: 12-2000 Posted From: 76.68.121.17  Rating: N/A |

I'm no engineer, but... Sounds like the radiator or air flow through it, wasn't big enough to cool the engine and the manifold. The question now is whether the heat you are leaving in the manifold and then downstream through your exhaust won't be a problem. Heat transfer to other coach parts? Grass fire? happy coaching! buswarrior | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 207 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

BW, How would the exhaust now be any hotter than any normal genset without water cooling? Would it be normal practice on any other unit to add the exhaust heat to the engine cooling system when using a radiator? I'm just trying to understand if I'm missing something implied in your post. In my manual, the same 7.5KW unit for land based use just doesn't have the extra water pump,and runs a standard exhaust manifold. Thanks! Glenn | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1556 Registered: 12-2000 Posted From: 76.68.132.24  Rating: N/A |

All things being equal, it won't be. The issue I raise is that you have changed what is going on with your set-up. You will have more heat in the exhaust than you did before, and whether that will cause any unintended consequences. Exhaust pipes against something that won't withstand the increase in heat? Exhaust parts close to the grass, exhaust aimed at something when parked in your usual place at home? Just thinking safety. happy coaching! buswarrior | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 208 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

OK BW, I get it. I'll check with my IR gun to see where the temp goes. My exhaust exits by the rear wheel, and the genset is in the first bay, so about 12 feet away. The exhaust tip was 96 degrees originally. I've got about 3 inches between the exhaust manifold to the fire retardant fiberglass sound deadening material. It is fiberglass drop ceiling panel. I'll also check the muffler temps under the bus since that's the closest spot to the ground. Additionally I'll check the temp were the exhaust passes through the bay floor. Anything else that you think I should check? Safety first! Thanks! Glenn | ||

| Dan West (Utahclaimjumper)

Registered Member Username: Utahclaimjumper Post Number: 170 Registered: 1-2005 Posted From: 208.66.38.60 Rating: |

I have a simular setup using a Perkins diesel powered genset with water cooled exhaust manifold, I would be conserned that the manifold itself does;nt have the physical properties to take the heat with out the water to cool it.>>>Dan | ||

| George M. Todd (George_mc6)

Registered Member Username: George_mc6 Post Number: 805 Registered: 8-2006 Posted From: 64.55.111.6 Rating: N/A |

Glenn, Dan has it, I would be very concerned about the compartment overheating now that the manifold is hot. G | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 209 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

We had crummy weather all day yesterday, but I think today I can get out and check temps on everything. Thanks! Glenn | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 210 Registered: 6-2006 Posted From: 216.163.56.194  Rating: N/A |

Allright, I think we are OK. Temp at the first muffler is 170. Temp at the tail pipe is 76. Engine temp is 160 at 42 ambient. Exhaust manifold is is 475-500 close to the exhaust port. The fiberglass insulation closest to the exhaust port is 115. All of the measurments are done with the load described up above. Does anyone see any issues? Thanks! Glenn |