| Author | Message | ||

| Sean Mormelo (Sventvkg)

Rating: N/A |

Hi all...I'm having a weird issue when I put the bus into drive. I have a 79 MC5C. I Push down on the emergency brake to release it, step on the brake pedal and shift into Drive like I always do. The Air PSI SHOOTS down to 90 by the time the emergency brake releases. It starts out at 120psi. Then I get the Air back up above 100 so I can go, and when for quite a while, it just drops down again below 90 and it seems the brake tries to come back on again and I can't get the bus out of 1st gear. I have to pull over, rev it up so the air will build back up again. This happens a few times before I can get going on the road. The PSI holds fine when i'm in Neurtral with the Air brake on but once i shift to drive, drop the air brake and depress the brake pedal for it to release i'm having these problems. Any advice? I have never bled the braking system and don't really know what it's for, but would that help? I can't think of what else can be causing it. Thanks. | ||

| John MC9 Rating: N/A |

I would: chock the wheels start the engine leave it in neutral depress the park brake button hold the service brake pedal to the floor for 5 seconds and release, go outside and listen for leaks. | ||

| Brian Brown (Blue_velvet)

Rating: N/A |

Sean, air brakes don't require bleeding... which is indicative of air in a liquid of some sort, like brake fluid, power steering fluid, coolant, etc. You do have an air leak, somewhere, though. Your bus likely has DD3 brake chambers on the drive wheels. Look for three air hoses going to the cans and you'll know for sure. If so, you can do a search here for help on those. The system is a bit more complex than spring brakes or the older cans, and has more plumbing. The best troubleshooting device you can find is your ears and some soapy solution. Use shop air to fill up your system (so you can hear the leaks), but keep it regulated under 80psi for testing... or your DD3's might not be able to release later (without assistance, anyways). Good luck, bb | ||

| Jerry Liebler (Jerry_liebler)

Rating: N/A |

Sean, Don't neglect the obvious. You need to drain all the air tanks, if you haven't they are all full of water and dramatically reducing the volume of stored air. When Air is compressed the moisture from the air ends up trapped in the tanks and must be removed evry so often. Each Tank will have a drain valve, When I first got my bus I drained over 3 gallons from it's main tank. Regards Jerry 4107 1120 | ||

| John MC9 Rating: N/A |

Sean- One other important thing: Make sure you have the wheels chocked AND the bus is well blocked and supported, so it stays -up- when the air is depleted! You don't want to get crushed by the bus while you're under it looking for air leaks. (Check the manual or here, for the proper block and jack points) | ||

| Sean Mormelo (Sventvkg)

Rating: N/A |

Jerry...Thanks..Draining the tanks is what I meant, not bleeding the brakes. I do need to do that as I've never done it but don't posess the chocking and blocking stuff to get the entire bus up. I only have enough on hand to get the bus blocked up to change a tire if necessary. Also, I do have some small leaks that i can hear that do need to be addressed. Thanks for the advice guys. | ||

| Sammy (Sammy)

Rating: N/A |

You probably have DD3 brake chambers as previously mentioned. One important thing to remember is that the parking brake (ICC) brake is spring applied, and air released. There is a large coil spring inside the brake chamber that will apply mechanical pressure to the drive brakes thru the slack, s-cam etc.This will occur with loss of air pressure to that side of the brake chamber. Air pressure is introduced to that side of the brake chamber when you want to release the parking ( ICC) brakes.The air pressure compresses the spring, allowing the brakes to release. Sounds like you have a bad diaphragm,air leaking thru diaphragm on the park brake side of the brake chamber.I cannot stress enough how careful you Must Be when working on this system. Excellent advice has already been mentioned - chocking wheels, support body, etc. DO NOT DISASSEMBLE THE BRAKE CHAMBER ASSY IF YOU ARE NOT A TRAINED PROFESSIONAL.Please excuse the large caps in the last sentence.I am not yelling, just want you to truly realize how dangerous this repair can be. The coil spring inside the brake chamber can kill you, if not handled properly. Go ahead and check for external leaks, maybe just an external air line has gone bad. If not, I strongly recommend taking it to a pro - if you are not familiar with this repair. Best of luck. Sammy | ||

| Brian Brown (Blue_velvet)

Rating: |

Sammy, DD3's do not have the giant springs in them, like spring chambers do. I've rebuilt one, so I know this for a fact. It's a three-chambered can, hence the name, with two diaphrams. There's a lock port that utilizes giant ball bearings to lock the pushrod for parking... an emergency air tank applies the brakes via the aux. diaphram when needed (low pressure on the service side OR the push-pull valve is activated). The springs inside are to keep the diaphrams in proper position and aren't under a great force at all. I rebuilt one with an old trucker standing by, certain I would face an untimely death when I took the can apart. He stood about 100 yards away and screamed "nice knowin' ya'!" He was quite surprised when the can just gently popped open. Here's the Bendix sheet on them: http://www.bendix.com/downloads/service_data_sheet/024600.pdf Brian "still alive and kickin'" Brown bb | ||

| Sean Mormelo (Sventvkg)

Rating: N/A |

Sammy..I had new bellows and complete brake repair all around, 7 months ago. got all the parts from MCI through Michael Kraft. I would be very suprised if I have a bad diaphram already! But I will check for external hose leaks as best I can. If I can make it to FL, I'm just going to have Horizon Coach asess my leak issues along with a few other small things that I need fixed, as they are more set up to easily get under the bus and figure things out. Thanks so so much to everyone here and I look forward to meeting you all in Arcadia. | ||

| Ian Giffin (Admin)

Rating: N/A |

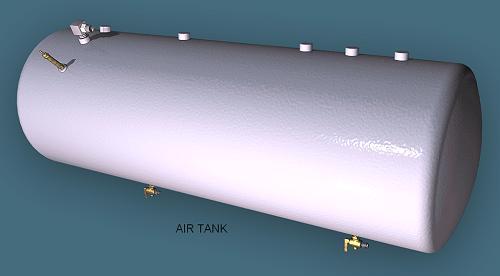

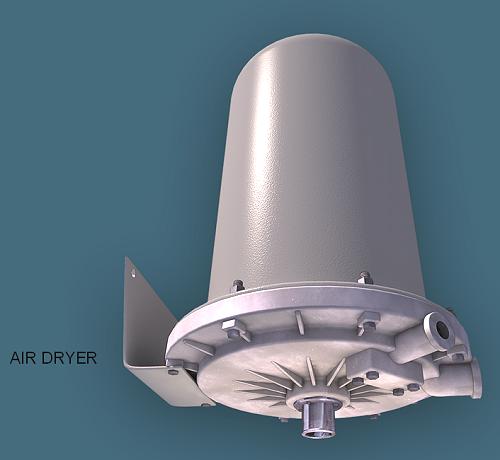

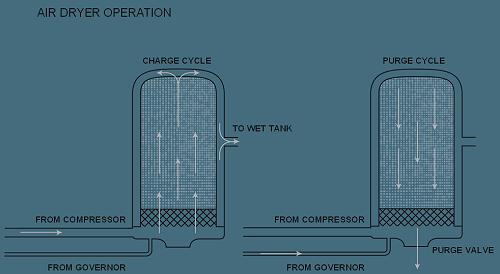

Air Tanks Air tanks are used to store compressed air. Each brake application requires a fairly large volume of compressed air, but the compressor can pump only a small volume at a time. In order to be useable at all times, the system must store compressed air in air tanks. Each air brake system has at least 3 tanks: the "wet tank" and the dual service (primary and secondary tanks).  Wet Tank Air from the compressor goes into the wet tank first. There is moisture present in the air drawn in by the compressor. This moisture condenses and collects in the wet tank. In some cases, oil from the compressor can also collect there, particularly if the compressor is worn. Drain Valves Each air tank has a drain valve to get rid of the excess moisture or contaminants that build up over time. A manual drain valve is operated by hand and must be used to drain the system regularly. Some vehicles have an automatic drain valve that performs the same task automatically while the vehicle runs, but the tanks must still be drained maually on a regular (daily) basis. The water can freeze in the air brake system causing it to malfunction. Oil mixing with the water forms a sludge which can cause the valves in the air brake system to stick. If contaminants are not drained from the tanks, the volume of the tanks will be reduced, leaving less space available for the storage of compressed air.  Air Dryer Most air brake systems today have an air dryer that traps water, oil and dirt in the air before it goes from the compressor and into the wet tank.   CAUTION Compressed air used in an air brake system is released from many of the system's parts. This air travels at high speeds and often contains moisture, oil, dirt, etc. which could harm eyes or ears. Know where air exhausts and avoid being in its path. In addition to chocking & blocking as has been suggested, don't forget to wear safety glasses and hearing protection. exerpted from the OSL Air Brake Endorsement Instructor's Manual Ian www.busnut.com | ||

| Sean Mormelo (Sventvkg)

Rating: N/A |

Wow...Thanks so much Ian!!...That was a nice schooling and I shall take it to heart! Sean | ||

| Sammy (Sammy)

Rating: N/A |

Brian, thanks very much for the correction and the Bendix link.It's been a while since I have last worked on a MC-5. I was thinking about the spring brake style chamber that we are used to seeing today.I just wanted to make sure that no one got hurt. Thank you again. Sammy | ||

| DMDave Rating: N/A |

Thats some nice posting Ian. Sean, where are you now in your travels? Dave and Dori Evans | ||

| Sean Mormelo (Sventvkg)

Rating: N/A |

Dave...right now, i'm holed up South of Lexington, VA in Natural Bridge at the KOA. Tomorrow I head out to Asheville, NC for a few days then Nashville. It's a crazy life but someone's got to do it! The bus needs some small TLC things taken care of and I hope to get them done in FL around or after Bussin 06. Take care. | ||

| John Jewett (Jayjay)

Rating: N/A |

Sean, Brian Brown is correct about the DD-3 rebuild, since I did mine last month with no problems. The mechanic at the local truck shop did one while it was still on the MCI-7-while lying on is back in the mud!!! My guess is that your Relay Valve is leaking or has moisture/dirt stuck in an "O" ring, causing it to malfunction. Let us know when you find out please, since we always wonder what the final disposition of a problem was. Cheers...JJ | ||

| R.C.Bishop

Rating: N/A |

Thanx, Ian..very helpful information! and much appreciated by everyone who reads the post, I am sure. RCB | ||

| R.C.Bishop

Rating: N/A |

Matter of fact....*very* good post from everyone...thanx for sharing!! John...always wondered if there was a "way" to do that...  RCB |