| Author | Message | ||

| Christopher Goodwin (Cgoodwin)

Rating: N/A |

Some time ago I did some research on leveling systems for my bus, I looked at hydraulic rams, commercial systems, even looked into making my own. I then found some discussion here about a system designed and built by Pete Papas involving solenoid valves used to independantly control the existing air bags. I contacted Pete who was quite friendly and very precise in the description of his system, its function and the functioning of the system on my bus. We talked several times, I posted diagrams of my bus suspension on a site I have for his inspection and in the end, after wasting much of his time, I ordered a set of valves from him. They arrived a week or so later and sat on my shop counter for weeks, finally this week I found the time to install them. I discovered that several "Mechanics" had already worked on my system and I now had 3 different size fittings and 2 different size air lines. I decided to make everything uniform before installing the valves, that done I set about installing the valves which was far simpler than correcting the errors made by others on my system. Once installed I sat in the drivers seat with my bus leaning badly to the passenger side on the slope in front of my shop. I lowered both front air bags to thier limit, then selected "Raise" on the passenger side air bag..... The passenger side rose and within 5 seconds the bus was level! For the first time in the 2 months it has been in front of my shop the bus was level! I flipped the control switch to hold and shut the motor down. 4 hours later it is still level (it used to settle in about 1 hour to the stops). I restarted the engine, flipped the control switch to "Auto" and the bus returned to its normal list and I drove a few miles, everything worked as it always had. Reparking I again switched to "Manual", dropped both bags and raised the passenger side until the bus was level. The system works flawlessly. Chris | ||

| bruce knee (Bruceknee)

Rating: N/A |

How much did it cost? Will it also level front to rear? | ||

| Pete/RTS Daytona (Pete_rtsdaytona)

Rating: N/A |

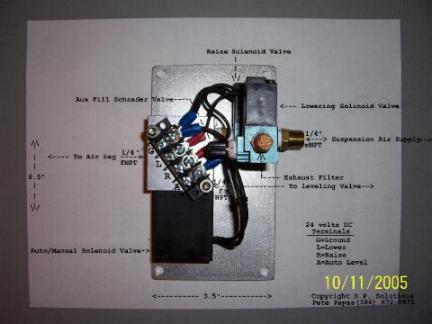

Hi All Thanks Chris for the "kind words" about my little devices. I'm just another guy Converting a Bus (1989 TMC RTS 35'102" 6V92TA DDEC-II 4.10/24.5). I experimented with many different types/makes of valves systems - I wanted to be able to level my RTS at a campsite - but not lose the auto leveling feature while traveling - My first design was big / bulky / expensive - This is the final version (GEN4 - 4th generation) - (small / compact / inexpensive)  for a larger picture see --> http://image57.webshots.com/157/8/62/75/515186275WyYRrM_ph.jpg I'll be bring them to bussin' 2006 in Arcadia here's a description of what I have available: D.P. Solutions GEN-4 "Campsite / Auto-Leveling Override System - the new simpler- to- install design - GEN4 You need to supply the labor and the wiring - I supply all the Valves - the design and detailed instructions / wiring diagrams - this system is for 24 volt buses (I'm working on also providing a 12 volt system). The Pneumatic Solenoids Valve Selection was very important- Valve selection criteria: . Auto/Manual valve must be bi-directional - (must be able to withstand pressure differentials / air flows from either direction) . Auto/Manual valve - must have a 100% duty cycle rating - It is always energized during normal bus travel . Raise Valve - must be bi-directional in order not the back flow if supply air leaks down . Flow rate - Must not impede the normal auto leveling air flow . Flow rate - Must be large enough to raise / lower air bags in a reasonable amount of time - . Operating Pressures - Appropriate High Pressure rating - Appropriate minimum operating pressure rating 1.The GEN-4 input (supply side) needs to connected to the suspension air supply - This is accomplished by tapping into the line that supplies the bus auto leveling valve 2. The GEN-4 device is installed in series between the Bus Leveling valve and the air bag 3. The Auto/Manual Solenoid Valve isolate the leveler from the air bag system - this valve is energized for auto leveling (normal bus traveling) and connects the Bus Auto Leveling valve to the Air Bag(s) to provide normal factory auto leveling function. 4. The Auto/Manual Solenoid Valve is de-energized during hold and manual leveling operations to block the Bus Auto leveling valve and provide a path for the manual raise/lower solenoids 5. In Manual (adj) mode the raise and lower solenoids can be energized to allow air into or deplete air from the air bag(s) for manual leveling operations 6. An optional "GEN-4" COMBINER VALVE is available to tie air bags, not normally controlled together during auto leveling, to be grouped together to balance the number of air bags controlled per corner <> Each GEN-$ unit is $119 (controls one corner) Add $59 for OPTIONAL GEN-4 COMBINER VALVES 3 units are recommended (I believe 4 point leveling can twist the Bus) but 4 point leveling is available <> This type of system allows for approx 10" of up/down movement in each of the RTS far bumper corners <> I suggest that 16 gauge 4 conductor trailer wire be used to wire each leveling device to the switches - I have 100' spools available for $27 (raise / lower / Auto / dedicated ground) <> Nice Looking Black Carling Rocker switches can be provide for the control of the solenoids at $8.00 each (Momentary on/off/on) (SPDT-center off) for: DUAL FRONT (raise/lower) LEFT REAR (raise/lower) RIGHT REAR (raise/lower) or any other combination (snap action-lighted on/off/on) (DPDT-center off) for: AUTO/HOLD/ADJUST functions I'm working on having a control panel plate made with the square holes for the switches - cut out with a CNC milling machine - but they will not be available until January, 2006. If square switch holes are too hard-I would suggest Toggle switches from Radio Shack will work and only require round mounting holes Radio Shack DPDT Momentary Flip Switch $4.49 Catalog #: 275-709 http://www.radioshack.com/product.asp?catalog%5Fname=CTLG&category%5Fname=CTLG%5F011%5F002%5F015%5F001&product%5Fid=275%2D709&hp=search Radio Shack DPDT Flip Switch $3.99 Catalog #: 275-710 http://www.radioshack.com/product.asp?catalog%5Fname=CTLG&category%5Fname=CTLG%5F011%5F002%5F015%5F001&product%5Fid=275%2D710&site=search I can supply the Radio Shack #'s if your interested Because installation of these devices will require that the purchaser modify the existing bus air suspension system design. I will absolutely require a signed "waiver of liability" prior to purchase. Pete RTs/Daytona Note to IAN - Please If I have exceeded the bounds of the "Flea Market" type criteria - please send me an email and tell me what I owe you for this "shameless Plug" about this little device I made to share with other Bus Nuts | ||

| Pete/RTS Daytona (Pete_rtsdaytona)

Rating: N/A |

hmmm try --> http://community.webshots.com/user/hawk_ii | ||

| Jim Stewart (H3jim)

Rating: N/A |

Pete, Is there any limit switch or mechanism to limit the amount of upward travel? My fear is that I might add too much air to the bag and damage something. Jim | ||

| Ron Walker (Prevost82)

Rating: N/A |

Pete, you might want to look at getting your control panel plates cut with a laser rather than using a CNC mill...it would be way cheaper and accurate enough for a square switch. I'll be ordering a air system off you next spring. Is the valve assembly water tight? I would have to mount it exposed to the elements. And can the solenoid coils be suppied in 12V? Thks for the info. | ||

| Pete/RTS Daytona (Pete_rtsdaytona)

Rating: N/A |

Jim It's my "personal" feelings that a pressure / limit device is not required. Just imagine what pressure our air bags are subjected too while in auto leveling when hitting a pothole at 60 MPH. or What the pressures must raise to when doing a panic stop and diving the weight of the Bus onto the front air bags If a sustained high pressure (Max raise - in manual) bothers you - may I suggest that you simply install a pressure regulator set to 100 lbs (or about 20% of max OEM suspension pressure) in the supply line for the Raise function. this will limit pressure in Manual Mode only. Ron Thanks for the suggestion about Laser cutting - The valves I use are generally very "weather resistant" - I have mine mounted facing the road under the bus in a open area - I not had any problems. Yes I hopefully will have the same valves available with 12 volt coils soon | ||

| John Elnitski

Rating: N/A |

Pete how can I call you about getting parts. my email is elnitski@statecollege.com | ||

| Rob King Rating: N/A |

Hi Pete Do you have a compressor mounted somewhere in the system to keep the air pressure up when the engine driven compressor is off? Rob 91 Prevost Missouri | ||

| Kyle Brandt (Kyle4501)

Rating: N/A |

Hi Pete, You have a good idea here, I sent you an email about laser cutting the panels. kyle4501 | ||

| Pete/RTS Daytona (Pete_rtsdaytona)

Rating: N/A |

Hi Rob King I don't use an Aux Compressor - I tap into the bus suspension air supply (the same supply that feeds the air bags There is no need to maintain an air source after the campsite leveling - because the leveling override device are betwwen the OEM leveling valve and the air bags - as long as the air bag doesn't have a hole and it's fitting and line to my device are not leaking - the bus will hold up to where it's set for months - even if the suspension air thank goes to zero psi It's usually the leveling valves and it's internal schrader valve that causes most bus to leak down Pete RTS/Daytona |