| Author | Message | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 125 Registered: 11-2008 Posted From: 74.13.196.43  Rating: N/A |

After all that (see previous posts) I thought I was ready to go... jumping up and down with joy (literally!) and packing my gear. The bus fired right up and... no air. I could hear the leak, sounded like one of those pressure cookers... you know, the kind with the wiggly top? Pshhh...pshhh...pshhh. I THINK it was from the valve in the air dryer (but I didn't dare crawl all the way under to verify). Anyway, hit the area with a heat gun and, finally, started to get air pressure. But after it purged (around 125 psi on my rig) it just kept dropping, all the way to zero. Then it would slowly start to climb, finally purge again and drop right back to zero. This went on for quite awhile until she finally found her normal cycle: 125 psi - purge - drops to 98 psi - begins to build again to 125 psi - purge... like that. I'm thinking (THOUGHT, anyway) the valve was just frozen and the multiple purges had expelled the excess water. The next morning (yesterday) she fired right up again, air pressure came up normally and away I went. Not on the road yet, but a step closer. I took her nearer to my place (to finish packing and loading). I pulled into my friend's drive and left her idling while I looked for an electrical outlet and plugged her in. And then the Low Air Alarm goes off! The air pressure had dropped to 20 psi in about 5 minutes. Between the noise of the wind (HOWLING) and the motor, I couldn't hear any leaks. So I shut off the main switch, thinking if I couldn't stop the wind I could at least stop the motor. Wrong again. The motor wouldn't shut down. Emergency shutoff... that's the ticket! No dice. Plenty of ugly smoke but that old engine just kept rattling away. Opened the engine compartment, hit the rear Emergency Shutoff. Same result... NO result. Finally put it in gear and dumped the clutch (hoping there wasn't enough power to send me hurtling into my friend's living room). And that killed it (well, hopefully, just put it to sleep). But by then all the air had escaped and I couldn't locate the leak... if there even WAS a leak? Seems like it would have to be a pretty massive leak to lose that much air so quickly, but I never heard it. If it helps for some armchair diagnosis: The bus responded normally throughout the drive to this place. But the place is windswept and blanketed with snow. When I parked (still idling) the wind was a good 50-60 knots, kicking up a regular ground blizzard under the bus. Any suggestions would be extrememly welcome. From your dismayed and desolate (not to mention distraught and desparate) friend, Nellie Wilson | ||

| RJ Long (Rjlong)

Registered Member Username: Rjlong Post Number: 1483 Registered: 12-2000 Posted From: 67.181.166.160  Rating: |

Nellie - Dumping the clutch to kill the engine simply put your baby to sleep for awhile. (Hope you used 3rd or 4th, less "ouch" on the clutch.) Your coach needs around 60 psi in the system to shut down normally, so if you were down to 20, then you did the right thing with the gearbox - something folks with an automatic can't do! Make sure you reset the emergency shut-off flapper in the engine compartment before you try to restart your baby. Does your "fast idle" work? If so, in colder climates, I always found that if/when I had to let the bus idle more than say at a stop light, keeping the fast idle on helped keep the air pressure up, HVAC working properly, etc. You probably will have to wait out the howling winds so you can trace down your air leak. My WAG is that it's related to the cold somehow. . . Good luck, and keep us posted! FWIW & HTH. . .  | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1459 Registered: 12-2000 Posted From: 76.68.122.210  Rating: |

The time in the shop has loaded it with damp air, which under our current deep freeze..... Add to that it has not been run steady through the cold weather, and has unknown air system maintenance.... The devil's in the air system, and you're in the driver's seat. Did you confirm the air drier heater is working? You need to dose the bus with alcohol downstream of the air drier. See my post down in this thread: http://www.busnut.com/bbs/messages/11/25146.html?1229707043#POST132306 If the air drier heater is not working, that purge valve will just keep on sticking intermittantly, foiling your escape. It all comes back to mainteance. Southern busnuts can buy a bus a toodle around. Canadian busnuts have little choice. Air system maintenance is either 100% or.... let us know! happy coaching! buswarrior | ||

| Ednj (Ednj)

Registered Member Username: Ednj Post Number: 230 Registered: 3-2003 Posted From: 68.197.95.38  Rating: N/A |

Nellie, See if you could hook up shop air to it. (Portable compressor) It will be quieter and maybe you could hear the leak. My bus has a valve inside the passenger side engine door where I can hook air to the bus. My you 2 are fast, you responded while I was typing. Good advise, good luck nellie (Message edited by ednj on January 14, 2009) | ||

| Leland Bradley (Lee_bradley)

Registered Member Username: Lee_bradley Post Number: 37 Registered: 11-2006 Posted From: 138.163.106.71 Rating: N/A |

Dumping the clutch to kill the engine simply put your baby to sleep for awhile. (Hope you used 3rd or 4th, less "ouch" on the clutch.) I'm not sure how the clutch knows or cares what gear the transmission is in; it deals with the same torque regardless. Certainly easier on the drive train and engine/transmission mounts. | ||

| Glenn Williams (Glenn)

Registered Member Username: Glenn Post Number: 181 Registered: 6-2006 Posted From: 216.163.56.194 Rating: N/A |

When you get it up and running, DON'T STOP RUNNING FOR THE BORDER!!!! ;) Glenn | ||

| Mel La Plante (Mel_4104)

Registered Member Username: Mel_4104 Post Number: 111 Registered: 7-2006 Posted From: 64.180.192.9 Rating: N/A |

stay away from that emergency shut down switch, it is there for emergency stoppig and this type of stop does not come under this heading. the reason that you do not want to use it is that the flapper inside the boot on the blower closes off the air to the engine causing a vacum betwwen it and the pistons which can and will suck the seals out of the blower which are not cheap to rebuild the blower and reseal. have you drained your air tanks lately {all tanks} ahd are all the exit shut off valves closed? by using a shop air compressor you should be able to hear the leak as you will not have the engine noise to deal with. good luck... | ||

| Tim Brandt (Timb)

Registered Member Username: Timb Post Number: 251 Registered: 10-2003 Posted From: 66.165.176.62  Rating: N/A |

I guess these air operated ones must be very different than my 6-71. I have an electric solonoid that shuts the lever on the govenor and if that were to fail it's just a simple matter of pushing the plunger in with my hand. Is manually shutting one down not an option on the type you have? | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 126 Registered: 11-2008 Posted From: 74.13.197.99  Rating: N/A |

Thanks Guys - RJ, I was in such a state I honestly don't know what gear I used. Probably not first... not for any good reason such as you've pointed out, but just because it's such a b**** to get into after idling for awhile. You see, I wanted to back in... not wanting a repeat performance of getting towed from the rear (see how my mind's working these days?). But I'm on this busy (and icy) two-lane highway... plus can hardly think (or see) from the freakin' wind. After several false starts, I just gave up and nosed her in. Justifying my cowardice, of course, by telling myself my fears were groundless - considering the last three days of maintenance and repairs, what could possibly go wrong? (D*** that Murphy guy. Who'd name a kid 'Murphy' anyway?) Thanks for the reassurance on my panicked solution. But you got me to wondering: What DO the automatic drivers do in a simlar situation? And why did my bus not shut off? I mean, SOMETHING happened. The power dropped way off and the engine was smoking and struggling. Would it have shut off with proper air pressure? As for the fast idle: On my bus it only works when the parking brake is engaged AND the bus has at least 60 psi. BW, I didn't even know the air dryer HAD a heater. Where the bus is presently parked (stuck) it would be hard to get to... but if I could, how would I ascertain if it works? I have no dashboard switch for that. Does it come on automatically, like with the main power switch? Is it thermostatically controlled or just always 'on'? (I suspect mine is always 'off') And where IS the heater? I see some kind of fitting, with electric leads, at the bottom of the air dryer canister. I thought that was the purge valve but could it be the heater? I wanted to put air line anti-freeze (same as alcohol?) into the system after I'd gotten it working again, but my mechanic disagreed. Said it could mess up the valves, etc. But, then again, he failed to mention the thing had a HEATER (when it would have been SO easy to check). So, BW, you think alcohol will do any good without air pressure, or should it wait until I get it working again? (Fingers crossed) BTW, good zinger... that "Southern busnuts can buy a bus to toodle around" bit.  Ednj, I have that same valve (actually used it once, so I know it works). But besides helping to find the leak, could I get enough air to release the brakes and move the bus to a better work place (hopefully inside)? But, hmmm... thinking on that, it was probably a dumb question. I suppose air from ANY source would leak out just as fast (duh). And, Leland, FYI: My clutch very much cares which gear we're in. She presently fancies 2nd, although she was once enamored with 3rd - now, suddenly, on her s*** list. [Hey, Ralph P., just got your email. Thanks a bunch. I'll reply soon, but wanted you to know I'll follow your advice soon as the temp. gets a little more bearable.] Thanks again, Nellie Wilson | ||

| John and Barb Tesser (Bigrigger)

Registered Member Username: Bigrigger Post Number: 117 Registered: 9-2007 Posted From: 24.179.147.233  Rating: N/A |

Nellie, I think Buswarrior had the right idea, I would try working some alcohol through the system ( you can do this at the air compressor if you can get to the hoses). If that fails to make any change and you still suspect the air dryer, you can get some of the correct size brass fittings and screw the hoses together and bypass the air dryer entirely until you get somewhere warm where you can remove it and rebuild it ( all the parts are available at any decent truck parts dealership) and its not a hard job to rebuild. If that is not your problem and it still won't build air, I would next check the governor on the air compressor that regulates the pressure. These will get froze up and fail to work correctly, but start with alcohol. Good luck, its -20 here today, nothing wants to work..including me! | ||

| larry currier (Larryc)

Registered Member Username: Larryc Post Number: 203 Registered: 2-2007 Posted From: 207.200.116.13 Rating: N/A |

You probably need to put a whole bottle of air brake alcohol in it behind the dryer, not in front of it. Since something is frozen open and bleeding off it will most likely work the alcohol right to the problem area. Sometimes you can let it run on hi idle and the warm air from the compressor will eventually work its way to the problem but that is rare with a coach, too much distance. | ||

| ED Hackenbruch (Shadowman)

Registered Member Username: Shadowman Post Number: 88 Registered: 11-2003 Posted From: 68.27.246.164 Rating: N/A |

Nellie i don't know if your 5C is the same as my 5A but if it turns out your air leak is in the front of the bus, there is a small pressure regulating valve located either by or between the 2 air tanks behind the front axle. If it leaks at all replace it. If it leaks too much you ain't leaving Dodge or any other place. :>) I just had to replace mine this summer, Luke has them in stock and they aren't much money....whole thing fits in the palm of your hand but like i said if its leaking you ain't moving. | ||

| RJ Long (Rjlong)

Registered Member Username: Rjlong Post Number: 1485 Registered: 12-2000 Posted From: 67.181.166.160  Rating: N/A |

Leland - "I'm not sure how the clutch knows or cares what gear the transmission is in; it deals with the same torque regardless. Certainly easier on the drive train and engine/transmission mounts." Thanks for catching that. Using a higher gear to stall the engine is easier on the powertrain, not just the clutch. Nellie - BW's on the money again - aren't you glad you've got a Canadian friend who knows the problems we sunshine state folk never deal with? Tip: If 1st is difficult to get into from a dead stop with the clutch out, try slipping the gearbox into 3rd or 4th, then moving over into 1st. Same trick the wet clutch GMC owners use, and it works! BTDTHT Chances are, if you'd have flipped on the fast idle switch when you set the parking brake in your friend's driveway - BEFORE you got out of the driver's seat - your air pressure may have stayed up. Based on the weather forecasts, looks like you may be at your friend's for a few days!  FWIW & HTH. . .  | ||

| John MC9 (John_mc9)

Registered Member Username: John_mc9 Post Number: 743 Registered: 7-2006 Posted From: 72.154.191.164  Rating: N/A |

I don't see why you can't heat that entire undercarriage just by standing aside the bus... (whew!) BW is absolutely on target! Any moisture will freeze, and keep the skinner valve from closing, and you'll lose the pressure until it's thawed. We suffered that with the Eagles during the winter months, until we (bus drivers) were instructed to dump the water after parking it for the night. Alcohol was a remedy, but it was like a band-aid. Moisture builds up, and if you don't empty it out, it will stay in and do what you're experiencing, alcohol or not. The air lines would freeze enroute to the ski slopes. But back then, we had "Johnson" to save us. Down-gear to real slow, and pull up on the parking bar.. A trip to the 'trails garage to defrost, was the usual day's fare. (oooooh, the fond memories) Use some space heaters to defrost the lines, then do your best to get the water out. Don't drive it, unless your able to stop it. (uhhhh..... that was always rule #1) Cheers! | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 127 Registered: 11-2008 Posted From: 70.49.112.215  Rating: N/A |

Thanks for the updates since my last post. [RJ, how do you write the special text (italics and BOLD? on your posts? I really like that but don't see any commands for doing it.] I was playing a gig last night and this fellow kept going outside. Figured he just hated my music but turned out he was cranking up the idle, bit by bit, on his Kenworth. He said he'd have to run her all night at 1000 - 1200 rpm to keep from freezing up (both him and his truck). Re: my problem. he suggested pumping helium or nitroogen through the lines (using the valve that Ednj mentioned). Said either gas picks up the water molecules and dries the lines. Anybody ever heard of that? Nellie Wilson | ||

| Skip N (Skip)

Registered Member Username: Skip Post Number: 33 Registered: 11-2006 Posted From: 161.7.80.97  Rating: N/A |

If you have enable html code then you can use most standard html coding structures like <8h1> Hi </h1> remove the 8 Hi Just one way you can use most of the font commands and backround commands. Flashing fonts will usually get you some flames though  enjoy Skip | ||

| Grant Thiessen (Busshawg)

Registered Member Username: Busshawg Post Number: 83 Registered: 10-2007 Posted From: 206.45.93.160  Rating: N/A |

I would stick with the proper air line antifreeze. It is designed for this purpose. Follow BW directions and you will eventually get it straightened out. Frozen air systems can be a real pain in the *** . Sorry Ednj, but I would not hook back up to shop air as that may have been what caused this in the first place. As BW has pointed out in the past, shop compressors can pump quite a bit of moisture into your system. Start simple if you want by putting some air line antifreeze into the valve or line that is easily accessable, you may get lucky. Don't expect results immediately. You will probably have to let it work for awhile. Check your heater on the drier and bypass if you wish . The system will work with out it but if once you get to the point in your journey where it started to warm up and the roads are wet and then it starts to freeze again you maybe in for the same situation all over again. Dryers or maintenance to the dryer is not all that expensive. In my opion by the time you crawl under it and bypass the dryer you could have fixed it. As BW has stated maintenance is very important, drain your tanks whenever you use it, daily if you use it daily. But all in all BW is right on the money! Have Fun | ||

| Ralph Peters (Ralph_peters)

Registered Member Username: Ralph_peters Post Number: 10 Registered: 12-2008 Posted From: 206.251.8.2 Rating: N/A |

Nellie,Yes nitrogen is what the phone company has dry their lines,when you see a grey bottle next to a pole or pedistol of the phone co. the bottle has a regulator (full bottles have 2000Lbs.pressure) an hose to the area needing drying/pressure to keep out contaniments. If you installed a bottle with a high volume regulator set to 110psi. tee in at ping tank, you may possibly drive it south. But not this week. Do not know the $$$ for a bottle. ralph | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 128 Registered: 11-2008 Posted From: 70.52.103.117  Rating: N/A |

I'm trying to decipher all this but have some very elementary (at least to you guys) questions: What's a skinner valve? Where is the air dryer heater and how do I determine if it's working? How do I turn it on??? Where would I squirt (pour, punp, whatever) the air line anti-freeze? How do I know 'up stream' from 'down stream' as regards the air dryer? What's a 'ping' tank? Ohh... and what does BTDTHT mean? As you see, the volume of my ignorance could fill an encyclopedia. I've decided to follow Glenn's advice: "When you get it up and running, DON'T STOP RUNNING FOR THE BORDER!!!!" Considering that (just arrived at) decision, does it make sense that I just do that... and not stop until I get to warmer climbs? I mean, rather than trying heroic measures (probably beyond my skill range) to instill winter reliability? I read BW's great post on this subject... all stuff I could possibly do, but I'd sure rather do it where it's warm (and when I'm not pushed to go anywhere.) Assuming that scenasrio (starting it up, finding some air pressure and GOING SOUTH), what would you guys do? I'm planning a stop at John's (in Maryland) where I've been offered some expert help. And last I checked, Maryland is about 30 degrees warmer than here. And the bus seems to have no trouble in 'normal' cold - you know, around freezing point or even a bit lower. Hey, John MC9, thanks for the sweet compliment. But it doesn't work...she just gives me an icy glare and pouts. One other thing: Mel 4104, you've given me a real worry. Do you think I ruined anything? I mean, what are those things (Emergency Shutoffs) for if not to stop the d*** engine? Geez! My ignorance just pisses me off somtimes. But my own mechanic was trying to START the bus with the emergency shutoff (go figure) and - I was told - that the auto shutdown feature trips that same switch. Why would they design a system that would destroy the blowers? At least without a cautionary label or something? And how do I reset the thing now that I've so stupidly tripped it? Thanks again. Nellie Wilson | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 129 Registered: 11-2008 Posted From: 70.52.103.117  Rating: N/A |

Hi Skip! That is way cool. Where do I find the 'enable html code' command? (I just cut and pasted your example). And how do I keep the 'Skip' on the same line as the 'Hi'? Nellie | ||

| Patrick levenson (Zubzub)

Registered Member Username: Zubzub Post Number: 39 Registered: 5-2007 Posted From: 76.66.201.170  Rating: N/A |

Don't worry about the emergency shutdown destroying the blower | ||

| Patrick levenson (Zubzub)

Registered Member Username: Zubzub Post Number: 40 Registered: 5-2007 Posted From: 76.66.201.170  Rating: N/A |

oops... If you read all of MAK and BNO pages you will find 2 different opinions on this but in general everyone seems to agree that a decent blower won't suffer from using the emergency shut down flap. By my reckoning if a blower fails from the shut down flap being used at idle...you needed a blower rebuild anyway. Possibly these tales of blower failures have to do with run away DDs way over revved due to sucking oil or something. BTDT means "been there done that", I have never known what the HT stands for. If you are not too busy, and in this cold I like to stay home, read the entire MAK forum and this entire forum, you will get a huge general education in BUS STUFF. If I could afford the time I would head south myself right now, probably will next year. BW says it best, drain those tanks after use, I don't know much about running these things in the winter but I figure yours is ready for a good hard run, as long as you have changed, checked the various fluids (dif, tranny etc..) KOB (just made that one up) | ||

| Skip N (Skip)

Registered Member Username: Skip Post Number: 34 Registered: 11-2006 Posted From: 161.7.80.97  Rating: N/A |

<8b>this is a test</b> this is second test <8i>Italicized</i> this is a test this is second test Italicized Remember to remove the 8 on the source Since Hi as header was working your enable html is on Just google HTML fonts to get tons of how 2's ;) Skip | ||

| Bruce Henderson (Oonrahnjay)

Registered Member Username: Oonrahnjay Post Number: 354 Registered: 8-2004 Posted From: 69.250.38.183  Rating: N/A |

Nellie wrote: "I'm trying to decipher all this but have some very elementary (at least to you guys) questions: What's a skinner valve? Where is the air dryer heater and how do I determine if it's working? How do I turn it on??? Where would I squirt (pour, punp, whatever) the air line anti-freeze? How do I know 'up stream' from 'down stream' as regards the air dryer? What's a 'ping' tank?" I had similar questions. I found a workshop manual for my bus and I spent hours working through the written description on the air and brake systems and the diagrams with them. I don't know if your bus has a similar manual but, if so, it would be beyond value for you. Also, there are various websites that describe the operation of air brakes. They are generally directed toward heavy trucks, but many of the parts and principles are the same or similar and you can learn lots. The websites of manufacturers (Bendix, etc.) have good info, too. Finally, getting good advice is helpful. I found a mechanic who had worked for Greyhound in a large city for over 20 years, ending as the workshop foreman. After he left there and stated his own shop, 'Hound contracted with him to do their "overflow" work and work that they'd prefer to have done out rather than in the shop; he also did (and his son continues to do) work on church and charter buses. I work through things and then go ask him questions on things I don't understand. Info is out there but it isn't always easy to find (as you've seen). (Message edited by oonrahnjay on January 15, 2009) | ||

| Ednj (Ednj)

Registered Member Username: Ednj Post Number: 231 Registered: 3-2003 Posted From: 68.197.95.38  Rating: N/A |

Here is the answer= http://www.foxnews.com/story/0,2933,479973,00.html | ||

| Don Evans (Doninwa)

Registered Member Username: Doninwa Post Number: 176 Registered: 1-2007 Posted From: 208.81.157.90 Rating: N/A |

Nellie, The emergency shutdown flap on my DD is real handy being a GM. You will find it right on top of the blower. Should be a little shaft sticking up from the arm to lever it open until it latches. A picture from another MCI driver would help a bunch. If you remember our previous discussion about needing air pressure to shut down the engine, a skinner valve is bus speak for a solenoid controlled air valve that in this case applies air to the air cylinder that pushes on the shut down lever. While you are looking for the emergency shut down reset look for the shut down lever on the governor. You can push it manually if you have no air to kill the engine. Be careful of the belts, another problem absent on the GMs. Trace the air line from that little cylinder and it will go to the skinner valve. As far as getting it running and heading South, I would caution you that if your air system has water problems, it can freeze up and stop you at the most inconvenient time. Good luck Don 4107 | ||

| RJ Long (Rjlong)

Registered Member Username: Rjlong Post Number: 1486 Registered: 12-2000 Posted From: 67.181.166.160  Rating: N/A |

Nellie - When posting, at the bottom of the page is a button for "Help/Instructions". Click on that, then click on "Formatting", and you'll find all the various formatting codes to play with. BTDTHT = Been There, Done That, Have T-shirt. Gotta go pack. . . Off to Quartzsite to mingle w/ other busnuts this weekend. Pics next week! FWIW & HTH. . .  | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 134 Registered: 11-2008 Posted From: 70.49.113.66  Rating: N/A |

Okay, come hell or high water I'm cookin' to Quartzsite. I missed Arcadia (obviously) but - unless distance is impossible - I'll try for Quartzsite. (Where the heck is Quartzsite?) Trouble is, I won't get thawed out until Sunday | ||

| Jack Conrad (Jackconrad)

Registered Member Username: Jackconrad Post Number: 924 Registered: 12-2000 Posted From: 71.54.29.215 Rating: N/A |

Quartzite is in Arizona. Although the Arcadia Rally is over, there are a couple other smaller Bus Conversion rallies coming up in February and March in Florida. | ||

| Paul Lawry (Dreamscape)

Registered Member Username: Dreamscape Post Number: 415 Registered: 5-2007 Posted From: 166.129.173.151  Rating: N/A |

Come to Texas Bus Roundup 2009 just north of Dallas in October! We'll show you a real Texas Style BBQ! | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 136 Registered: 11-2008 Posted From: 74.13.196.64  Rating: N/A |

Okee doke, Paul! Count me in. And thanks for the invite. Nellie | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 139 Registered: 11-2008 Posted From: 74.13.196.64  Rating: N/A |

Howdy Zubzub - I surely do appreciate your take on that blower thing. Was sitting here going nuts, wondering if I should brave the cold and spend another frigid day trying to start the thing just to determine how much damage my ignorance had caused. And thank you too, Skip and RJ and Bruce and Don. In case you don't know it (and how could you?) I condense all your advice and print it out to carry in the bus. It's slowly growing into my personal 'Bus Bible' so you'd better get your copyrights in order.  Hmmm... maybe Ii should talk to Ian about that? It could make a great book... Nellie Wilson | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1460 Registered: 12-2000 Posted From: 76.71.102.247  Rating: N/A |

Ok, I'm back. Nellie, it's cost/benefit time. If you try for the south without knowing what's really wrong, it will cost you a whack to go disabled on the road. The cops will order their own tow and you'll be paying... To the southern observers, there is no way, short of one of those 5 or 6 digit BTU construction heaters setting fire to the underside of the bus to maybe get heat into it, with the temps below 0 farenheit. The breeze simply takes the heat away, the massive heat transfer required to effect any significant change is quite dangerous to achieve outdoors, using furnace level inputs and a lot of cardboard to try to block the wind. So, in truly guerrilla northern busnut fashion, I offer this quick and dirty strategy: Option one: You can wait until warmer weather. Option two: since option one leaves the readers bored and with nothing left to type about, let's try this: To the wires on the air drier, temporarily remove what's there, tape up the ends for another day, run a new wire on the outside to a good known electric source. Right across the snow, up the side of the bus, in the driver's window or into the electric panel under the driver, whichever is nicer in the cold. If there is one wire, great, go to the power, the grounding is through the drier. If there are two, once you get them cut off and extend both upstairs to where it's easier to work on, make sure one of them doesn't ground to the body some other way, or we'll have a short. figure out which is what using your multi-meter. Before doing all this, you also have the bus plugged in, both the block heater and battery chargers. Connect your new wires to power(and ground if necessary) Now that you have for sure power to the air drier, let it sit for 10 minutes, VERY closely supervised, we're flying without a fuse, smoke or heat in the wires would be a bad thing, To the safety gurus, at this point in the exercise, we don't have time for blown or mismatched fuses. It either works, it doesn't, or we get a bit of smoke. Ok, then start the bus and see what happens. You have re-set the emergency stop? See the next post, I'll fetch a picture and some words for this. If it holds air, you're not out of the woods yet. If you can get back inside a shop, make a more permanent repair to the wire, and get it fused for 3 amps, get some brake alcohol into the tanks according to my earlier post, cycle the air system as directed and then you'll be good as gold....for now.... and when it is warmer, the process of bringing the air system up to snuff with air drier maintenance can begin. And thank you to my fans! I am humbled. happy coaching! buswarrior | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1461 Registered: 12-2000 Posted From: 76.71.102.247  Rating: N/A |

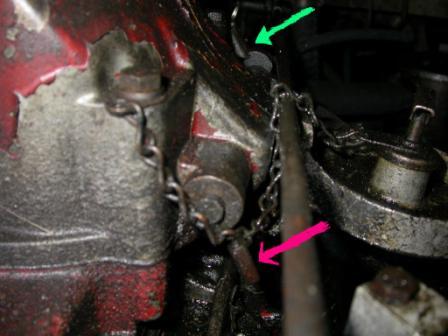

ok, here's the emergency stop:  This is looking in from the rear in an MC8, at the top of the air intake leading from the air cleaner to the top of the blower. The red arrow points to the little handle on the emergency stop device. The handle needs to be pushed down, such that the clip arrangement over at the green arrow engages to hold the flap that is inside the cover stays open. Sometimes, the clip arrangement, which is attached to the electric solenoid that pulls the clip to trip the flap, needs some help by your finger to go into place. This device is intended to let an observant operator try to stop an engine that is running away uncontrollably, due to some failure of the fuel delivery system. It does this by choking off sufficient intake air that the engine either stops or barely chugs along. The purpose being to prevent the engine from running at such uncontrolled high RPM that it damages itself. These failures are due to poor maintenance of that system, re-using parts that should have been discarded, or ignoring the signs of a failing system - sticking, or otherwise uncontrollable moments of engine fueling. I don't have a good pic of the fuel shut off arm to show you where to put your finger to shut the engine off manually. Who does? happy coaching! buswarrior | ||

| Mike Eades (Mike4905)

Registered Member Username: Mike4905 Post Number: 180 Registered: 12-2000 Posted From: 97.106.122.149 Rating: N/A |

Nellie If you are not running, Please give some thought to getting a metal oil rain pan and a couple of cheap tarps. get a couple of bags of charcol. Light the charcol in the metal rain pan. Slide it under the oil pan of the engine. Make sure you are not close enough to cause a problem. Put the tarps around between the bus and the ground. Keep an eye on everything. I have created enough heat to start up a big cummins. Mike4905 | ||

| John MC9 (John_mc9)

Registered Member Username: John_mc9 Post Number: 746 Registered: 7-2006 Posted From: 72.146.76.80  Rating: N/A |

Mike, with all due respect..... Nellie...... do not do that. wait, let me say that again: NELLIE, DO NOT DO THAT. Thanks Mike. No hard feelings, OK? | ||

| Bruce Henderson (Oonrahnjay)

Registered Member Username: Oonrahnjay Post Number: 357 Registered: 8-2004 Posted From: 69.250.38.183  Rating: N/A |

John MC9 wrote: "Nellie...... do not do that. wait, let me say that again:" Working on the basis of Bruce's Golden Safety Rule -- "Would you do this with your mother sitting in a lawn chair reading a library book right in the middle of this?"; I agree. | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 147 Registered: 11-2008 Posted From: 70.49.113.186  Rating: N/A |

Hi BW - I surely do welcome all the information and photos. I know writing and uploading photos takes a lot of time and I appreciate your doing it. And that goes for everybody. Though I'm responding mostly to BW’s last post, I’d like to hear from anyone that has an opinion .Okay, here's my quandary. I'm up against the clock and up against the weather. There seems to be a school of thought out there that, had I simply toggled my Fast Idle, I wouldn't have frozen up again. Though I don't get the logic, recent experience suggests that might be the case. To summarize my other posts (to spare you wading through my diatribe), the Air Dryer Purge Valve (I believe) froze after a prolonged (3 days) in-shop service. Extremely humid shop + bitter cold temp = frozen valve. I finally got her going (with the help of heaters) and after several purge cycles she came right. Thereafter, she ran fine and aired properly. Long stretches of fast idle and/or being driven caused no recurrence of freezing. The temp never moderated but no further freezing until I parked in truly blizzard conditions and neglected to hit Fast Idle. Important, maybe, to note: She’s been in similar weather much of her poor life – at least the portion spent with me – and never frozen up or had problems airing up. What I’m getting at: Maybe the Air Dryer heater works but only at operational RPM (Fast Idle or more)? I say this because she froze the first time under severely adverse comditions and after sitting all night. And the second time under even worse conditions and because of my negligence (normal idle). I like your idea of our re-routing the wiring, and assume I’m looking for a 24V source? But doesn’t that solution presume a power problem? If the problem is the thermostat or the heater unit or the purge valve (which actually seems okay) re-wiring wouldn’t seem to help – except to eliminate wiring as the culprit? I know I’m rolling the dice. (I sure can’t afford “a whack to go disabled on the road”) but IF I can get her started, and IF she’ll air up, I could try a ‘never stop, never slow down’ run for it. In three hours I’m in ‘normal’ winter temps where freezing up is very unlikely. Or, second scenario, take her back to that humidity laden shop and try to find and correct the problem (but that’s repeating the process that began the problem in the first place). Right now, my bus is in the most awful place imaginable to do any work on her. (If you knew how hard I'm kicking myself right now you'd call 911.) When I say (above) “I don’t get the logic,” I mean I’m unclear on the correlation between RPM and air (particularly why higher RPM prevents freezing). I’m just trying to understand the principles involved. Our fellow BusNut, Ralph Peters, just sent me another very thoughtful email and I'd like to ‘publicly’ acknowledge his kindness. To quote Bugs Bunny, that’a …that’a … that’s s all folks. To which you’re saying, and that’s quite enough, Nellie. Nellie Wilson | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1466 Registered: 12-2000 Posted From: 76.68.133.189  Rating: N/A |

We don't have a starting problem, we have malfunctioning air system problems. High on the suspect list is the purge valve in the air drier getting stuck due to a mix of moisture, freezing temperatures, and/or a questionable drier heater and/or some other normal exhaust port sticking. Even if applying external heat gets it to function, it will quickly revert to being dysfunctional shortly after driving it away, as the part that was thawed simply re-freezes, sometimes even better than the first time! Working on a frozen vehicle is no treat, and most everything you do takes many times longer due to all the clothes, trying to manipulate and drop tools with gloves on, finding tools dropped in the snow, freezing whatever skin is exposed, snow down your neck, up the back of your shirt, in your boots... real fun when you get fed up, take off your gloves and promptly get the cold wrench frozen to your damp cold hand.... Inside to recover, and find something better to do for the rest of the day.... For those who have been spared these conditions, perhaps a good analogy might be trying to read a newspaper in a hurricane and trying to keep it dry and in one piece for the next reader. You can do it, but it'll take some effort! happy coaching! buswarrior | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 150 Registered: 11-2008 Posted From: 70.49.113.186  Rating: N/A |

Gosh, BW, you ARE a quick responder. Well edited too, which makes me wonder how the heck you do it (takes me forever). But is that Air Dryer heater supposed to work at low idle? I'm thinking it may work but I'm just overstressing it (well, me AND the unusual amount of moisture AND the bitter temps). If I can keep the air cycling, won't the Air Dryer (eventually) purge the moisture (assuming the dessicant is still good)? Nellie Wilson | ||

| John MC9 (John_mc9)

Registered Member Username: John_mc9 Post Number: 748 Registered: 7-2006 Posted From: 72.146.76.80  Rating: N/A |

Nel - Re: "I’m unclear on the correlation between RPM and air (particularly why higher RPM prevents freezing). I’m just trying to understand the principles involved. " If the engine's idling, and any power is being used, there might not be enough amps left for that air drier to function to it's full potential. Soooo.... fast-idling will churn that alternator faster, producing more amps, and giving that air drier the power it needs to heat the air... And of course, the air pressure will build faster, adding to the heat! But.... in the real old days of buses, there was no "fast idle". We used a stick, cut to fit between dash bottom and foot pedal. And sometimes....... we even remembered to take it out of gear! sometimes. | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 152 Registered: 11-2008 Posted From: 70.49.113.186  Rating: N/A |

Hi, John MC9 - Maybe I should keep one of those sticks on my dash, just to remind me of what to do? That was about the best news I've heard for awhile. And it answered my most worrisome questions. I'm (almost) convinced my Air Dryer / Heater is okay and that I just hit the 'Perfect Storm' of moisture and sub-zero temps and operator ignorance. I know there is excess moisture in my system - and wiil follow BW's water extraction instructions - but maybe (assuming sufficient RPMs) I could first make it down to warmer climbs? Would sure value your opinion. Nellie Wilson | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1467 Registered: 12-2000 Posted From: 76.69.142.187  Rating: N/A |

Nelie, have you identified where the air is escaping from yet? The air drier heater is typically protected by a 3 amp fuse, so its power consumption is rather a non issue. There is a thermostat built in to regulate it. The air drier dries the incoming air, the moisture in the system can only leave via the drains, or via the exhaust ports of the valving when you use some air pressure. (we'll pretend that unintended leaks don't exist for the moment) The trouble is that you are waiting for the replacement air to dry out the moist air, which depends on a fairly high turn over of air. Think trying to dry your hands under one of those feeble hand driers, in which the heater has failed... you'll be holding your hands under there for a long time waiting for the passing air to evaporate the moisture, and then remember this is all taking place inside a closed system...once the humidity is high, it'll take some large turn over of air to convince the moisture to leave. And, it is already frozen, and the drains will be stuck, if there is any moisture present. So the moisture is frozen, you get the coach going and manage to get some functionality.(usually having nothing to do with whatever methods are being employed, it has cleared itself) Then you finally get some little bit of warmth creeping deeper into the air system through the action of the compressor compressing air, or minimally by waste engine heat under the coach, whatever, which melts some of the moisture that is shallow in the system, which then flows deeper to where it is still cold...and freezes onto the seat of another valve, so then you get a different failure, but you started driving the coach and are now forced roadside. If the failure acts as a plug to air flow by freezing some valve closed, you are scuppered, as now there's no way whatever minuscule warmth is ever going to travel deeper in the system. If it sticks open....you might get lucky, depending on how cold it is, and eventually the leak self corrects..but then the flow of air stops, then the offending valve gets colder...warmer air carries more moisture than colder air...the moisture refreezes and sticks the valve, or freezes on the next use of the valve and the adventure continues. If the air drier purge valve freezes in the cut-out position, there'll be no air flow to melt it, No air will reach the tanks and the air pressure in the line between the compressor and the air drier will climb to wherever the compressor can reach, as there's no way to signal the compressor to stop, and there's no safety valve to release it. The old timers always said drain it at the end of use. Well, the purge valve moves to cut-in when the air pressure in the wet tank drops below cut-in...the old timer dropped the air pressure while the system was still warm....the purge valve is in the correct position to let air flow into the system. Under winter conditions, fanning the brake pedal, or draining off enough air that the air system is building and then shutting off the engine is a little habit that pays dividends you'll never know about... And just imagine the fun if the freezing is going on in the air compressor controls...with the governor working, then not, then working.... you can't even get the compressor to supply you reliably with air. This freeze thaw thing is why air brake alcohol appears to be some miracle fluid, and is misunderstood. Folks have poured it in forever, and then got their amazing results and conclude whatever they conclude. It won't melt anything by itself, unless it was already warm, and it won't stay warm for long once poured into the system. It gets poured into all manner of wrong places by truckers, only because they have more places to wrongly put it than bus drivers do. Added to a contaminated system in enough volume that the vapours get deep enough, in sufficient concentration, the anti-freeze vapour hopefully mixes with your recently unfrozen moisture, and lowers its freezing point, and prevents refreezing. Whew, what a bunch of useless trivia, unless you venture into the cold country... Nellie, to return to the important question of the moment, where's the air escaping from? happy coaching! buswarrior | ||

| Ednj (Ednj)

Registered Member Username: Ednj Post Number: 232 Registered: 3-2003 Posted From: 68.197.95.38  Rating: N/A |

Here is some good reading for a cold and snowy day Bendix BX-2150 Air Compressor http://www.bendixvrc.com/itemDisplay.asp?documentID=2384 Information services for intercity and transit buses. http://www.coachinfo.com/AllAboutBuses/MCI_Info.html Now a question. what would be wrong with getting some Air Brake Conditioner,  And introducing it into the bus system via that drain/shop air valve in the engine compartment. Air up the bus with shop air and conditioner, then drain the tanks a few times and be done with it. What am I missing? | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 154 Registered: 11-2008 Posted From: 76.64.240.232  Rating: N/A |

Hi BW and Ednj - BW, I'll answer your question as best I can. I believe the leak (that pshhh-pshhh-pshhh sound previously mentioned) comes from the purge valve at the botom of the air dryer. I dared not crawl deep under the bus to actually feel it (with no blocks and leaking air). But I'm reasonably sure because heating that area seemed to cure the problem. Or - and this just occurs to me - the problem may have cured itself. I say that because I had barely begun to apply heat when she started to build air again. By then she'd run quite awhile, revs applied by the throttle (fast idle being OOS). So I'm thinking maybe it just took awhile for the air dryer heater to do its job? One thing though: Where is that 3 amp fuse located? Could this be as simple as a blown fuse? The way my luck's going, probably not... but worth checking? Ednj - Thanks for the info. I looked at your links and learned a lot. One thing I couldn't figure out - The Bendix Diagram didn't show the governor... can you describe where that attaches to the compressor? Thanks again, Nellie Wilson | ||

| Bob MacIsaac (Wildbob24)

Registered Member Username: Wildbob24 Post Number: 24 Registered: 5-2007 Posted From: 74.184.58.175 Rating: N/A |

Nellie, I, too, am enjoying your posts and the many replies to them. The governor mounts on the compressor where the unloader ports are located. Your compressor is most likely a Tu-Flo 550, like this: http://www.bendixvrc.com/itemDisplay.asp?documentID=5114 The photo in this document shows where the governor mounts. Bob | ||

| Ednj (Ednj)

Registered Member Username: Ednj Post Number: 233 Registered: 3-2003 Posted From: 68.197.95.38  Rating: N/A |

| ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 156 Registered: 11-2008 Posted From: 74.13.198.151  Rating: N/A |

Thank you, Bob, for both the great Bendix information and for the nice compliment. Anyone who thinks chivalry is dead should just pop in here for awhile. If you guys don't watch it, a buncha women will start buying buses just for the ego boost... I heard that internet thing might take off. I think you're right when you say, "Your compressor is most likely a Tu-Flo 550." I was going to confirm before responding but still too cold; ended up loading some sound gear and heading out to find a hot toddy (cold weather amplifies my aversion to unbolting things). But - since you knew that - maybe you'd also know whether a Tu-Flo 650 would be an appropriate replacement? I don't need it now (I hope) but it was a good deal and I picked it up as a spare (figuing if it doesn't fit, I can always trade it for something else). If it will work, I'll just keep it for 'in case.' Nellie Wilson | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 157 Registered: 11-2008 Posted From: 74.13.198.151  Rating: N/A |

Shoot, Ednj, you snuck in behind me. I type too slow. Thanks! I'll come back, gotta gig. Nellie | ||

| john w. roan (Chessie4905)

Registered Member Username: Chessie4905 Post Number: 1295 Registered: 10-2003 Posted From: 71.58.110.9  Rating: N/A |

The heating element in the air drier is at the exhaust or purge port to keep the escaping air, which cools on decompression, from freezing and blocking the port. Air driers need several cycles on a system that never had one to remove all the moisture. If you have a worn compressor, the constant contamination of the compressed air from compressor oil getting past the piston rings can reduce or stop the effectiveness of the desiccant in the drier. If contemplating installing an air drier, replace the compressor or find the cause of getting the oil or oil water mix coming out of the drains. The GM coach manual states to leave the drains open overnight to allow much more complete draining of any oil residue in the tanks. Alcohol isn't very effective at removing ice from air systems; getting the coach in above freezing temps, allowing the ice to melt and allowing the alcohol to mix with the moisture is what works. BTW Bendix no longer recommends using alcohol in the air systems. It is stated on their site. | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1470 Registered: 12-2000 Posted From: 76.68.132.217  Rating: N/A |

The promised pics for shutting off the engine via manual methods, and resetting the emergency stop have been posted on a new thread entitled: Manual engine stopping V71 happy coaching! buswarrior | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 164 Registered: 11-2008 Posted From: 74.13.197.93  Rating: N/A |

Well, my gosh - The temp came up to a balmy 20 F - as in PLUS 20 F - and I re-set my boo-boo (tripping the emergency shutoff). The old gal cranked a couple times and Vroom! But, as BW pointed out, starting wasn't my only concern... airing up was the big worry. But she did, sweet as pecan pie. So I let her run through about 10 cycles, purging and - to move more air through the system - feathering the service brakes (a tip fom you guys). I made sure the compressor was loading again before I shut her down (another tip from the board). Today I'm going to find some of that air-line anti-freeze (or alcohol) and try to figure out how to inject that into the schraeder valve thingy. Or is that a good idea? JW (Chessie) cautioned me that Bendix no longer recommends this procedure. And since most of what I try does more harm than good, i'd love some feedback (before I screw up again). I'm not out of the woods yet, but things seem much improved. I ran into some other problems but they're outside the scope of this thread... so I'll just start a new one. But for now, thanks to everyone for all the great info! Nellie wilson | ||

| John MC9 (John_mc9)

Registered Member Username: John_mc9 Post Number: 756 Registered: 7-2006 Posted From: 74.230.99.189  Rating: N/A |

Back in the '60s, the outfit I worked for stopped using alcohol in their buses, and just had us empty the tank of water at the day's end. I remember the mechanic saying that the rubber seals, diaphragms, etc, were damaged by alcohol, and although it kept him busy, the boss didn't like "down time". Gas line anti-freeze was changed from alcohol to whatever is used now, because the old alcohol gas line antifreeze would destroy the carburetor's rubber seals. I would imagine any rubber will deteriorate from alcohol. There's still thousands of trucks and buses using alcohol in the system, so whatever turns yer groove, eh? | ||

| Don Evans (Doninwa)

Registered Member Username: Doninwa Post Number: 177 Registered: 1-2007 Posted From: 208.81.157.90  Rating: N/A |

Nellie, you did not mention draining the tanks while you had air up. Did you do that? If so, how much gunk (technical term) did you get from the drains. If there is much, it indicates dryer need service/repair. Draining ALL the tanks regularly (daily) can work almost as good as a functional dryer and should keep you working. Good luck heading South, Don 4107 | ||

| Nellie Wilson (Vivianellie)

Registered Member Username: Vivianellie Post Number: 185 Registered: 11-2008 Posted From: 70.49.115.2  Rating: N/A |

Hi Don - Well, I didn't exactly DRAIN them but I opened the valves (a short blast on each) to see if any 'funny stuff' came out. But got only clean air so figured I was okay. Should I have done more? I plan to follow BW's advice and really clean up the whole system and refresh the air dryer, etc. when I get to warmer climbs. I can't accomplish much here (too cold) and my only indoor facility will just suck more water into my system (it's extremely humid). Let me know yout thoughts? Nellie Wilson | ||

| Don Evans (Doninwa)

Registered Member Username: Doninwa Post Number: 180 Registered: 1-2007 Posted From: 208.81.157.90  Rating: N/A |

That should do it. Good luck Don 4107 | ||

| R.C.Bishop (Chuckllb)

Registered Member Username: Chuckllb Post Number: 444 Registered: 7-2006 Posted From: 75.208.249.15 Rating: N/A |

Nel...chances are, if your air tanks are "exposed" to the cold, you may have ice in the bottoms and they would not let much water out. As you get to warmer climes, things should change for you. My manuals say "drain every day" after a drive, of course. FWIW  RCB | ||

| Buswarrior (Buswarrior)

Registered Member Username: Buswarrior Post Number: 1483 Registered: 12-2000 Posted From: 76.66.19.131  Rating: N/A |

The drains will be frozen and blocked if there's stuff solid in the bottom. If Nellie got air, that's a good sign as far as the rest of her troubles go. There isn't much in those tanks that doesn't belong. happy coaching! buswarrior |